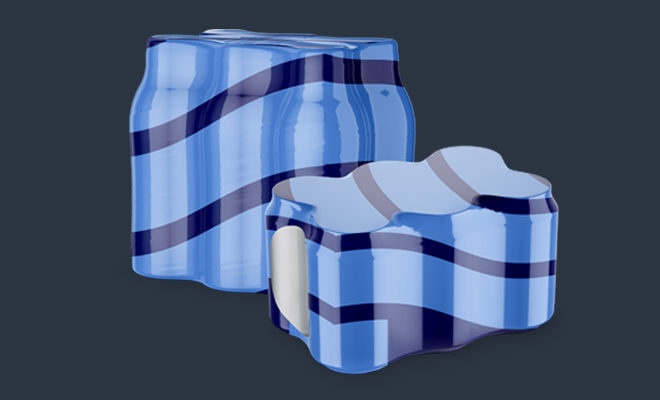

Usljed jasnog fokusiranja na zaštitu životne sredine, razvili smo Bio Program. U njemu pratimo kreiranje naših novih proizvoda u svakom koraku, od ulaznih sirovina, preko ekstrudiranja, štampanja i konfekcioniranja, kako bismo se uvjerili da svaki proizvod ima sve neophodne karakteristike za adekvatno korištenje ali da pri tom ne može izazvati negativne efekte po okolinu.